Choose premium auto detailing for a precise interior and exterior cleaning.

A Comprehensive Guide to the Kinds Of Ceramic Finish on the Market

Ceramic finishes have arised as a crucial solution throughout various markets due to their unique properties and applications. As we explore the unique qualities and applications of these layers, the ramifications for efficiency and long life become progressively noticeable, increasing questions about which kind could ideal fit your requirements.

Understanding Ceramic Coatings

Ceramic layers are sophisticated protective remedies that have obtained appeal in numerous sectors, specifically in vehicle and aerospace applications. These layers include a liquid polymer that, when cured, forms a durable, hydrophobic layer externally of the substrate. This layer provides improved resistance to ecological contaminants, UV radiation, and chemical direct exposure, thereby extending the life and visual appeal of the underlying product.

The fundamental element of ceramic coverings is silica, which adds to their hardness and toughness. The application process commonly entails surface preparation, application of the coating, and treating, which can be attained via heat or UV light. As soon as cured, ceramic layers exhibit remarkable bonding properties, enabling them to adhere strongly to a range of surfaces, consisting of metals, plastics, and glass.

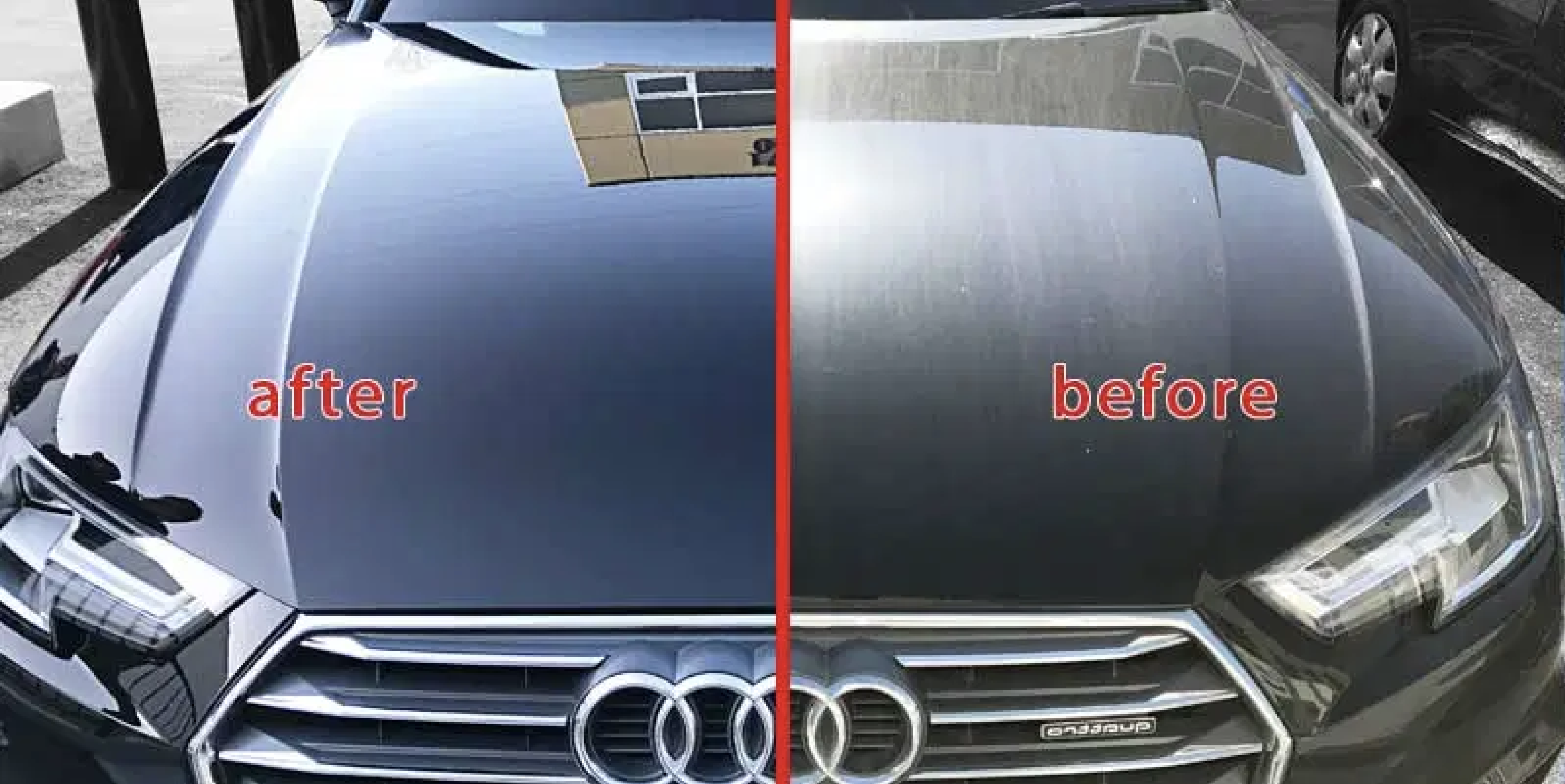

Along with their safety features, ceramic finishings also provide ease of maintenance. Their hydrophobic nature minimizes the adherence of dust and gunk, making cleaning less complex and much less regular. On the whole, the adoption of ceramic finishings represents a significant advancement in surface area protection modern technology, providing both useful and aesthetic benefits across numerous sectors.

Kinds Of Ceramic Coatings

Numerous types of ceramic finishings are offered, each made to fulfill certain efficiency demands and applications - Car Detailing. One of the most common types consist of:

Silica-based Coatings: These finishes mostly contain silicon dioxide and are understood for their sturdiness and chemical resistance. They are extensively made use of in automotive and commercial applications.

Titanium Dioxide Coatings: Renowned for their photocatalytic buildings, titanium dioxide finishings are frequently applied in settings where self-cleaning and antifungal residential or commercial properties are preferable, such as in structure materials and automotive surfaces.

Zirconia Coatings: Identified by their high-temperature stability and thermal resistance, zirconia coverings are used in applications such as generator engines and high-performance vehicle parts.

Alumina Coatings: Exhibiting exceptional hardness and thermal security, alumina coatings are often used in wear-resistant applications, including cutting devices and industrial equipment. - Auto Detailing

Hybrid Coatings: Incorporating the buildings of various materials, crossbreed coverings use enhanced performance features, making Check Out Your URL them ideal for unique and demanding applications.

Each sort of ceramic covering serves unique objectives, permitting individuals to select the most suitable solution based on specific environmental conditions and performance requirements.

Benefits of Ceramic Coatings

Ceramic finishes, in certain, deal numerous advantages that make them increasingly prominent among manufacturers and customers alike. These finishes are immune to scrapes, chemicals, and UV rays, making sure that the underlying surface area remains secured over time.

Along with resilience, ceramic finishings give excellent hydrophobic buildings, allowing for simple cleansing and maintenance. This water-repellent nature decreases the adherence of dust, crud, and various other impurities, which can extend the aesthetic allure and capability of the surface. Moreover, ceramic finishings can substantially enhance thermal resistance, making them excellent for applications that endure heats.

Application Refine

When applying ceramic layers, a meticulous method is vital to achieve ideal outcomes. The application procedure commonly begins with thorough surface area preparation. This entails washing, sanitizing, and brightening the surface area to get rid of all impurities, consisting of dust, grease, and prior waxes or sealers. A clean surface ensures appropriate attachment of the coating.

As soon as the surface is prepped, the next step is to use the ceramic covering. The finishing ought to over here be applied in slim layers, as thicker applications can lead to unequal finishes.

After application, the finishing requires a certain healing time, commonly ranging from a couple of hours to a full day, depending on the product. Throughout this moment, it is crucial to stay clear of exposure to wetness or pollutants. A gentle buffing might be needed after treating to enhance the gloss and eliminate any type of high places. Adhering to these steps carefully will take full advantage of the effectiveness and durability of the ceramic layer, giving a durable safety layer for the Extra resources surface area.

Maintenance and Longevity

To ensure the longevity and performance of a ceramic covering, routine maintenance is essential. Ceramic layers, understood for their durability and safety high qualities, call for specific treatment regimens to maximize their life-span and performance.

In addition to routine cleaning, periodic evaluations are crucial. Look for indications of wear or damages, such as hydrophobic homes decreasing or surface imperfections. If needed, a light polish may be put on renew the layer without stripping it away.

Additionally, the application of a booster spray can improve the finish's hydrophobic impacts and restore its gloss. This is particularly useful for coatings that have been in usage for a prolonged duration. Ultimately, by adhering to these maintenance practices, one can substantially expand the life of a ceramic layer, ensuring that it proceeds to offer optimum defense versus environmental elements and maintain the aesthetic charm of the car.

Verdict